How to Choose the Best Skid Steer Loader for Your Needs?

Choosing the best skid steer loader is not a simple task. With many options available, understanding your specific needs is crucial. Industry data from the Association of Equipment Manufacturers indicates that sales of skid steer loaders have increased by over 20% in the past year. This growth reflects the loader's importance in various industries, such as construction and landscaping.

Expert Mark Johnson emphasizes, "A skid steer loader should match your unique job requirements for maximum efficiency." This highlights the need for careful consideration when selecting a machine. You must analyze the weight, lifting capacity, and attachment compatibility. Each project may demand different features, which can complicate decision-making.

Moreover, it's essential to consider the correct sizing. Some users opt for models that may be too large or small for their tasks. This can lead to inefficiencies and operational challenges. Understanding these nuances is vital for making an informed choice. Selecting the wrong skid steer loader could mean wasted resources and time, which is a significant concern in today's competitive market.

Understanding Skid Steer Loaders: Types and Applications

Skid steer loaders are versatile machines used in various industries, from construction to agriculture. Their compact size allows them to navigate tight spaces easily. The skid steer loader market is expected to grow at a rate of 5.5% from 2021 to 2028. This growth highlights their increasing importance in diverse applications.

There are different types of skid steer loaders. The most common are vertical lift and radial lift models. Vertical lift loaders offer better reach and lift height. They are ideal for loading trucks and stacking materials. Radial lift loaders, on the other hand, excel in digging and grading tasks. Choosing the right type depends on your specific tasks. One report indicates that around 60% of operators find versatility crucial when selecting a loader.

Size and power play vital roles in performance. Smaller models are easier to transport and operate in confined areas. However, they may lack power for heavy lifting. Larger models can handle bigger loads but require more space and drive power. Each option has trade-offs that should be carefully weighed. Operators often need to rethink their choices based on these factors to ensure efficiency.

Key Factors to Consider When Choosing a Skid Steer Loader

Choosing the right skid steer loader requires careful consideration of several key factors. The first is lifting capacity. You need to determine how much weight the loader will need to lift for your projects. Having too little capacity can lead to breakdowns or unsafe conditions. Think about the types of materials you'll handle. Some machines excel with soil, while others are better suited for gravel.

Next, evaluate dimensions. The size of the loader matters, especially for confined workspaces. A compact machine can navigate tight areas, but may lack power. Balance is essential. The power-to-size ratio should fit your tasks. Review attachments as well. Different jobs require different tools, and not every skid steer accommodates all attachments.

Finally, consider operational ease. Controls should feel intuitive. A machine that is hard to operate can slow you down. Remember, your crew may have varying experience levels. Don’t overlook maintenance needs either. Frequent breakdowns can impact productivity. Think about these factors as they will shape your experience with the loader.

Skid Steer Loader Comparison by Key Features

Evaluating Engine Power and Performance for Your Needs

When selecting a skid steer loader, engine power and performance are critical factors. The engine's horsepower directly affects the machine's ability to lift heavy loads and navigate challenging terrains. A powerful engine may seem ideal, but it can lead to increased fuel consumption. This balance is essential to consider for long-term operational costs.

Also, examine the torque of the engine. High torque numbers often mean better performance in tough conditions, like steep inclines or soft ground. However, some models may struggle with efficiency despite high torque. It’s important to analyze efficiency alongside capability for optimal use.

Don’t overlook the type of tasks you plan to accomplish. If your work requires frequent lifting, prioritize models with robust lifting capacity. For lighter tasks, a smaller engine may suffice. Each skid steer brings unique advantages and quirks. Reflecting on your specific needs will help you make an informed choice. Choosing the right engine power can be a complex decision, filled with various trade-offs.

Assessing Attachments and Versatility of Skid Steer Loaders

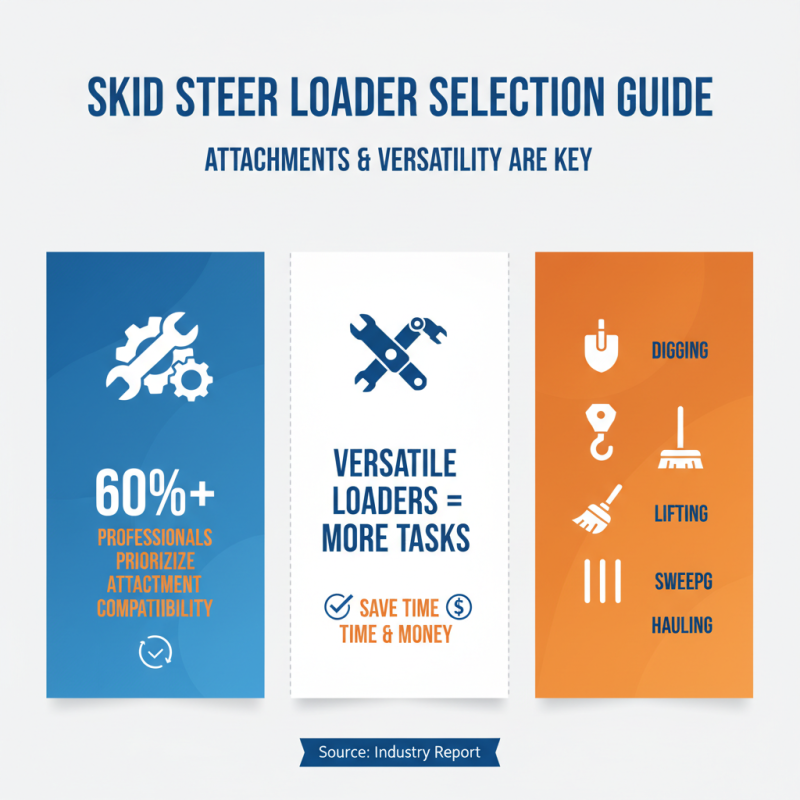

When choosing a skid steer loader, assessing attachments and versatility is crucial. A recent industry report states that over 60% of professionals prioritize attachment compatibility when selecting equipment. Versatile loaders can perform multiple tasks, saving time and money. They can handle everything from digging to lifting with the right attachments.

Loader attachments vary significantly in function. Buckets, forks, and grapples are among the most common. Industry reports show that the right mix can increase productivity by 30%. However, not all loaders can handle every attachment. It is vital to check the loader's compatibility. Oversizing or undersizing an attachment can lead to inefficiencies.

The flexibility of attachments enhances the loader's overall utility. Professionals have noted that while some may focus on horsepower, others must consider the ability to switch attachments quickly. This versatility can improve project turnaround time. However, some operators find it challenging to learn how to properly attach or switch tools. Training is often overlooked but essential. Time spent learning will pay off later.

Budgeting: Cost Considerations for Buying or Renting a Skid Steer

Budgeting for a skid steer loader involves assessing both buying and renting options. The costs can vary significantly based on the model and usage. Reports indicate that the average price for a new skid steer loader ranges from $25,000 to $60,000. For businesses with tight budgets, renting can be a cost-effective option. Rental rates typically fall between $500 and $1,200 per week, depending on equipment specifications.

Consider factors such as project duration and frequency of use. A short-term project may not warrant a purchase. However, long-term use of a skid steer loader could justify buying one. A 2021 study found that companies can save up to 20% by purchasing instead of renting over a year. Yet, initial costs may present a barrier. Maintenance and insurance add to ownership expenses, which might surprise many new buyers.

Evaluate your specific needs. Equipment selection should align with the tasks at hand. Not every skid steer loader will suit your requirements. Misjudging your operational needs could result in unanticipated costs later. Always reconsider how often you will use the loader. Being uncertain can lead to financial strain. Proper budgeting can prevent mistakes and set realistic expectations.

How to Choose the Best Skid Steer Loader for Your Needs? - Budgeting: Cost Considerations for Buying or Renting a Skid Steer

| Type | Price Range (Buy) | Estimated Monthly Rental Cost | Fuel Type | Lift Capacity (lbs) | Typical Use |

|---|---|---|---|---|---|

| Compact Skid Steer | $20,000 - $35,000 | $1,200 - $1,800 | Diesel | 1,500 - 2,200 | Landscaping, Light Construction |

| Midsize Skid Steer | $30,000 - $45,000 | $1,800 - $2,500 | Diesel | 2,200 - 3,000 | Construction, Demolition |

| Large Skid Steer | $45,000 - $70,000 | $2,500 - $3,500 | Diesel | 3,000 - 4,000 | Heavy Duty Excavation, Large Scale Projects |

| Electric Skid Steer | $25,000 - $40,000 | $1,500 - $2,200 | Electric | 2,000 - 3,000 | Indoor Work, Environmentally-Friendly Projects |

Related Posts

-

Why Skid Loaders Are Essential for Modern Construction: Exploring Industry Trends and Efficiency Stats

-

Why Choose Compact Utility Tractors for Your Farming Needs?

-

Revolutionizing Golf Course Care: The Ultimate Guide to Choosing the Right Lawn Mower

-

The Ultimate Guide to Choosing the Perfect Hay Baler for Your Farming Needs

-

Unlocking Efficiency: The Ultimate Guide to Choosing a Tractor with Mower for Your Lawn Care Needs

-

2026 Best Most Affordable Compact Tractor Options for Your Needs?