Top 10 Uses of HPMC for Sale in Various Industries?

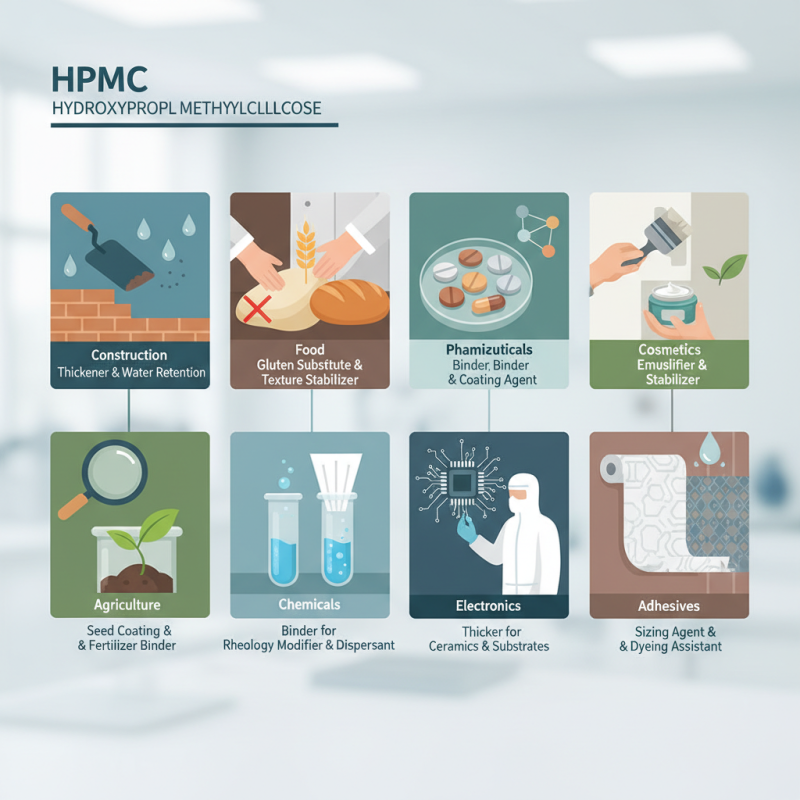

The versatility of hpmc for sale makes it a valuable asset across various industries. This multifunctional compound, or hydroxypropyl methylcellulose, serves multiple purposes, enhancing product quality and performance. Industries like construction, food, and pharmaceuticals have found innovative applications for HPMC.

For construction, HPMC acts as a thickener and water-retention agent in mortars. In the food industry, it serves as a substitute for gluten, improving texture and stability. The pharmaceutical sector values HPMC for its binding properties in tablets and as a coating agent.

While the demand for hpmc for sale continues to grow, some businesses overlook less optimal applications. Selecting the right grade can make a significant difference. It's crucial to understand specific needs for effective use. Recognizing the importance of proper formulation and dosage can require careful consideration. Overall, HPMC's functionalities can revolutionize product development in various sectors, yet companies must reflect on their choices to maximize benefits.

Applications of HPMC in the Construction Industry

Hydroxypropyl Methylcellulose (HPMC) has gained popularity in the construction industry. This compound serves as a versatile additive in various applications. It improves the workability of cement, plaster, and mortar mixtures. By enhancing the water retention properties, it helps in achieving better adhesion to surfaces.

Additionally, HPMC offers increased plasticity and flexibility to construction materials. This is crucial for ensuring durability in varying environmental conditions. Moreover, its use in tile adhesives leads to superior bond strength. However, HPMC's performance may vary depending on the formulation and mixing techniques used. Proper testing is vital to ensure optimal results.

In some cases, contractors have reported inconsistencies when using HPMC. These issues can arise from varying quality of raw materials. Thorough quality checks and adjustments in ratios may be necessary to address these concerns. Understanding the specific needs of each project can lead to more effective utilization of HPMC, ultimately improving the overall effectiveness of building materials.

HPMC's Role in Pharmaceuticals and Personal Care Products

Hydroxypropyl methylcellulose (HPMC) plays a vital role in the pharmaceutical and personal care sectors. This versatile compound is widely used as a thickener and stabilizer. In drug formulations, it ensures uniform distribution of active ingredients. This crucial function aids in effective medication delivery. HPMC also extends the shelf life of products, an essential aspect for manufacturers.

In personal care products, HPMC enhances texture and usability. It's often found in lotions, creams, and shampoos. Its ability to retain moisture helps keep skin hydrated. However, finding the right concentration can be tricky. Too much HPMC can lead to a greasy feel, while too little may not deliver the desired effect. Thus, ongoing adjustments are necessary to meet consumer expectations.

The versatility of HPMC is also evident in its use as a film-forming agent. This property is beneficial for both topical and oral applications. But, formulators must weigh the benefits against potential drawbacks. Balancing performance with user experience often requires trial and error. In an industry driven by innovation, HPMC remains a critical ingredient in the pursuit of better products.

Top 10 Uses of HPMC for Sale in Various Industries

| Industry | Application | Benefits | Typical Concentration |

|---|---|---|---|

| Pharmaceuticals | Binder in tablets | Improves tablet integrity and stability | 1-10% |

| Personal Care | Thickening agent in creams | Enhances texture and application | 1-5% |

| Food Industry | Food thickener | Improves viscosity and mouthfeel | 0.5-6% |

| Construction | Additive in cement mix | Enhances workability and water retention | 0.1-1% |

| Cosmetics | Stabilizer for lotions | Promotes emulsion stability | 0.5-3% |

| Agriculture | Soil conditioner | Improves soil texture and moisture retention | Up to 1% |

| Plastics | Additive for films | Enhances flexibility and durability | 1-5% |

| Textiles | Finishing agent | Improves texture and water repellency | 0.5-2% |

| Paints & Coatings | Rheology modifier | Enhances flow and stability | 0.2-1% |

| Pharmaceuticals | Suspending agent for liquids | Promotes uniform distribution of active ingredients | 0.1-3% |

Utilization of HPMC in Food and Beverage Industry

Hydroxypropyl methylcellulose (HPMC) has become a popular ingredient in the food and beverage industry. This versatile compound serves various purposes, enhancing textures and stabilizing products. Recent industry reports indicate that the demand for HPMC in food applications is growing at a rate of about 4% annually.

HPMC is commonly used as a thickening agent. It improves the mouthfeel of sauces and dressings. Many consumers prefer creamy textures, leading manufacturers to look for natural alternatives. Interestingly, HPMC is derived from cellulose, making it suitable for vegetarian and vegan products. Moreover, it has a low calorie count, which aligns well with the trend towards healthier eating.

Another application is in gluten-free baked goods. HPMC helps mimic the elasticity of gluten, providing better structure. This appeals to a broad audience, including those with dietary restrictions. However, the challenge remains in balancing taste and texture. Some consumers still notice a difference in texture, leading to mixed reviews. These nuances must be addressed for greater acceptance in the market.

Top 10 Uses of HPMC in Food and Beverage Industry

Impact of HPMC in the Agriculture Sector

Hydroxypropyl methylcellulose (HPMC) plays a crucial role in agriculture. Its unique properties make it a versatile additive in several agricultural applications. Farmers often use HPMC in seed coatings. This enhances the adherence of nutrients and pesticides to seeds, promoting better germination. The film-forming ability of HPMC also protects seeds from adverse weather conditions.

HPMC is also used in creating soil conditioners. These products improve soil structure and moisture retention. By adjusting the viscosity of liquid fertilizers, HPMC ensures uniform distribution. However, some farmers struggle with the exact ratios needed for optimal results. There’s a learning curve involved. Not all practices yield the expected benefits.

In horticulture, HPMC enhances plant growth by improving nutrient absorption. Yet, reliance on additives may lead to complacency. Overuse could negatively impact soil health in the long run. As with any agricultural tool, balance is essential. Adaptation and reflection on its use are necessary for sustainable farming.

HPMC in Paints, Coatings, and Adhesives

HPMC, or Hydroxypropyl Methylcellulose, plays a crucial role in paints, coatings, and adhesives. Its unique properties enhance these products significantly. For instance, HPMC is an effective thickener. It helps create a stable consistency in paints, making them easier to apply. A thick paint can cover surfaces better, leading to improved finishes.

In coatings, HPMC improves adhesion and film-forming capabilities. When applied, it creates a smooth surface that resists wear and tear. Furthermore, it enhances the water-retention properties, allowing for longer-lasting applications. However, a challenge arises in balancing viscosity and workability. Formulators must ensure that the thickness does not hinder application.

The role of HPMC in adhesives is equally important. This additive provides the necessary stickiness and opens time for application. It allows better bonding on various surfaces. Sometimes, though, achieving the desired bond strength can be tricky. Adjustments in formulation might be necessary to address this issue. The adaptability of HPMC makes it a popular choice, but ongoing refinement is always needed.